ABOUT US

Tecnología Integral (TISA) is an innovation and development company aimed to provide solutions to complex industrial problems, from the initial theoretical models to the delivery of installed and working solutions in the facilities.

MISSION

To deliver value to our customers’ production processes through our products and services, with the high quality and complete technical support that characterizes us as a specialized manufacturer.

VISION

To be recognized as a company of excellence, with great technical capacity and a high market share in Latin America.

NUESTROS CLIENTES

Con más de 30 años de experiencia, hemos logrado posicionarnos, en más de 20 países, como líderes de soluciones avanzadas de monitoreo en línea de procesos industriales, dentro de las industrias en las que ofrecemos nuestros productos.

OUR HISTORY

Since its foundation, the company started to focus its work in some industrial sectors, raising needs that could lead to technological developments that would incorporate significant developments for the industry, especially through the contribution of physics and engineering.

Sawmill Industry

In 1989, TISA started working on a project based on infrared curtains to measure the JAS diameters of sawlogs, which was done manually at that time. The equipment was called Logscan.

A Venezuelan sawmill was the one that got the first scanner, being the beginning of TISA exports in 1991. Subsequently, several local sawmills began to get the technology and within a few years TISA had replaced all the foreign equipment. Five years after the technological development began, TISA had exported its Logscan equipment to Venezuela, Argentina, Uruguay and France.

By 1999, TISA had also created ScanWood, a system for measuring the thickness, width and length of boards produced by a sawmill.

Cement and Lime Industry

Between 1990-1991 TISA developed a software called TEMPERA that displayed a color map of the rotary kiln shell temperature, measured by a pyrometer, one of the first computers on the market, with 286 technology.

TISA also began to develop the hardware for a furnace shell monitoring system. This system was the first version of our current TEMPERA Scanner. Within five years, equipment had already been installed in lime, cellulose and cement plants in Chile and also in five other countries, competing with leading companies in the world.

By 1999, more than 25 TEMPERA systems had been sold in Latin America and more than 30 Logscan systems.

During this decade, TISA continued producing new developments for industries and improving its existing product lines. Thus the following were created:

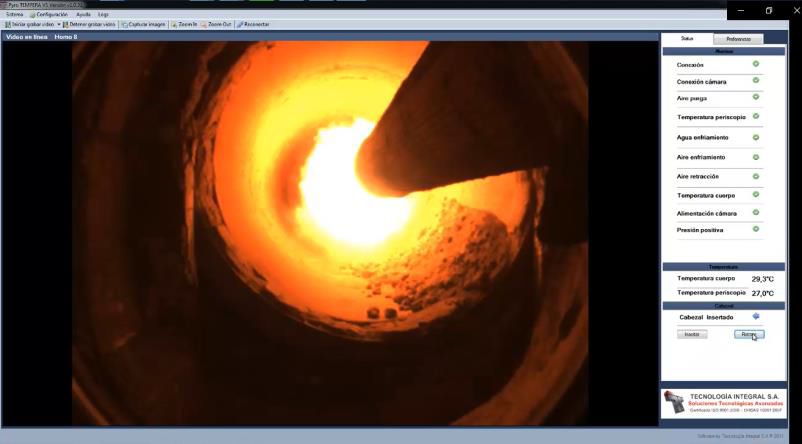

- 2003 Pyro Tempera SML system for measuring the temperature inside calcining kilns through images.

- 2003 Logscan- TS (True Shape) for the determination of the real shape of pieces.

- 2003 Scanwood CE for determination of the exposed face and dead edge of processed boards.

- 2004 OptiCAS software for optimization by cutting plans.

- 2005 Scanwood Warps for measurement and determination of warpage on processed boards.

- 2005 Virtual Line, replacing older moving lasers and even older wire shadow systems.

- 2009 Development of PyroSpec, intelligent head for our Pyro TEMPERA.

Also by 2009, TISA had consolidated its presence in Chile and Latin America, being recognized as a technological solutions provider, with more than 200 installations of its products in 18 countries around the world.

By 2012 TISA managed to create a technological solution based on soil penetration radars that detected injectable elements in Apron Feeders, our current SID Apron Feeder.

In that context, during 2014, TISA came up with a new technological product in the minning area, which would revolutionize the concept of monitoring

the operational status of idlers on ore conveyor belts. The solution aimed at the complete automation of monitoring by capturing both mechanical and acoustic vibrations of machining, allowing to determine with the highest precision the operational status of a pulley in a preventive way.

The support of a sector of the industry and CORFO, through Innova-Chile, allowed to incorporate significant technological improvements to the initial product giving rise to the SMAP product that since 2017 is installed and operates in several mining sites.

By 2019 TISA is a leader in Latin America, with more than 300 monitoring equipment sold in different industries and with customers in more than 20 countries.

In TISA we are continuously making innovations and improvements to our current products, looking for solutions to the issues that our customers come up with, always with the aim of being recognized as providers of high quality technological solutions and for providing excellent service to our customers.